In a world where sustainability and cost-efficiency are more than just buzzwords, Returnable Packaging Solutions are emerging as a compelling option for businesses of all sizes. While larger corporations have long adopted these systems to improve logistics and reduce waste, small businesses are now beginning to explore the benefits. But is it truly the right move for them?

This blog explores the key considerations, benefits, and potential challenges of implementing returnable packaging for small businesses.

Table of Contents

ToggleWhat Are Returnable Packaging Solutions?

Returnable packaging, also known as reusable or returnable transit packaging (RTP), refers to packaging systems that are designed for multiple uses. These include crates, pallets, containers, and totes made from durable materials like plastic, metal, or engineered wood.

Returnable packaging, as opposed to single-use packaging, is returned to the sender and reused. This closed-loop system helps in cutting down waste, lowering long-term costs, and streamlining logistics operations.

Benefits of Returnable Packaging for Small Businesses

1. Cost Savings Over Time

One of the most appealing benefits is the potential for long-term cost savings. Though the upfront investment in durable materials can be higher, the reusability of the packaging reduces the need for continuous purchases. Over time, the cost per shipment drops significantly compared to disposable packaging.

2. Environmental Impact

Today’s consumers and clients increasingly prioritize eco-conscious businesses. Switching to returnable packaging can significantly reduce a company’s carbon footprint and demonstrate a commitment to sustainable practices. This environmental responsibility can become a strong selling point for small businesses looking to enhance their brand reputation.

3. Improved Product Protection

Durable packaging materials offer superior protection compared to cardboard or other single-use options. This reduces the risk of product damage during transit, which in turn minimizes returns and enhances customer satisfaction—vital metrics for any growing enterprise.

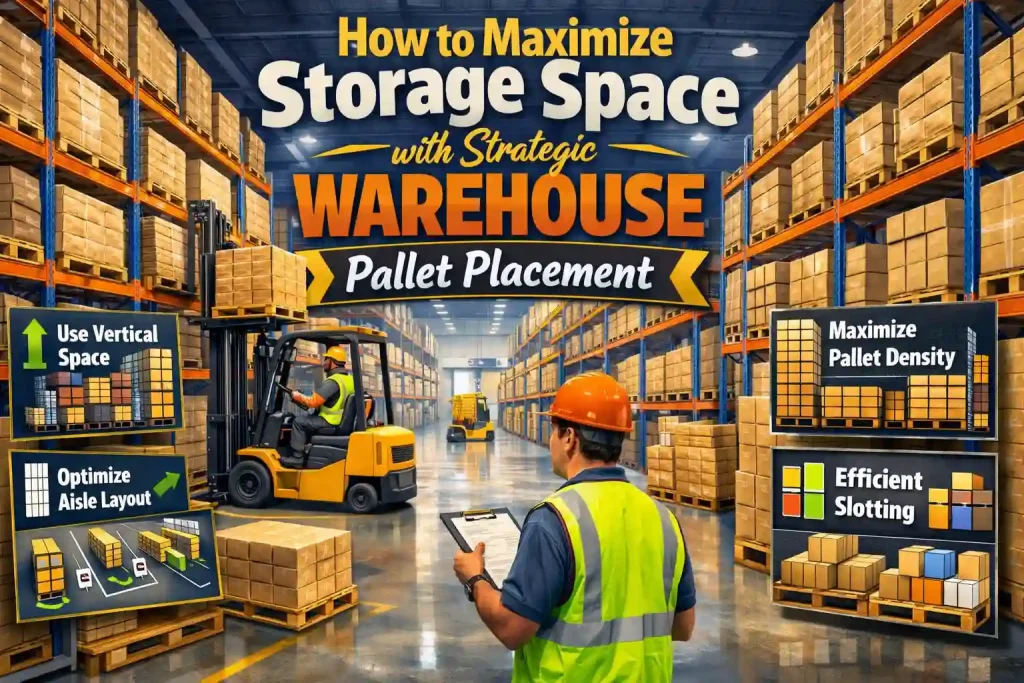

4. Streamlined Logistics

Using standardized returnable containers helps optimize storage, improve warehouse management, and facilitate quicker handling during shipping and receiving. This can be a huge advantage for small businesses aiming to improve operational efficiency.

Potential Challenges and Considerations

Despite its advantages, implementing Returnable Packaging Solutions is not without its challenges—especially for small businesses with limited resources.

1. Initial Investment

Purchasing reusable containers and establishing a return system can be capital-intensive. Small businesses operating on tight budgets may struggle with the initial costs. However, these costs can often be offset by long-term savings.

2. Return Logistics

Managing the reverse logistics—getting the packaging back after delivery—can be complex. It requires coordination with clients or third-party logistics providers and may involve additional tracking and labor. For businesses that ship to various locations or rely on third-party retailers, this could be a hurdle.

3. Storage Space

Reusable containers must be kept when not in use. Small businesses with limited storage capacity may find it difficult to accommodate these materials, especially during peak seasons when warehouse space is at a premium.

4. Partner Cooperation

The effectiveness of returnable packaging is dependent on the collaboration of supply chain partners and customers. If the packaging isn’t returned or is frequently lost, the system becomes inefficient and costly. Building reliable partnerships is crucial to avoid such pitfalls.

Is Returnable Packaging Scalable for Small Businesses?

One concern many small business owners have is the issue of scalability. Will the system grow with their business?

The good news is that returnable packaging is always expandable. Many providers offer flexible plans that allow businesses to start small and expand as needed. By beginning with a small pilot program—perhaps within a regional delivery area or for a specific product line—businesses can assess viability before committing fully.

Additionally, technology has made it easier to track and manage returnable assets. With RFID tags, barcodes, and cloud-based inventory systems, even small businesses can maintain control and ensure efficient return cycles.

Industries Where Returnable Packaging Makes Sense

Not all businesses will benefit equally from returnable systems. It’s particularly effective in the following sectors:

- Food & Beverage: Reusable crates and pallets ensure hygiene and prevent spoilage.

- Automotive: Durable containers are ideal for heavy and delicate parts.

- Retail & Wholesale: Standardized packaging can simplify shelf stocking and reduce waste.

- E-commerce: Companies with high return rates can benefit from durable packaging.

Small businesses in these sectors may find returnable packaging especially beneficial.

Tips for Implementing Returnable Packaging Solutions

If you’re considering a switch, here are a few best practices:

- Start Small: Begin with a limited rollout to test logistics and gather feedback.

- Educate Your Team: Make sure employees understand how to handle, track, and return packaging.

- Choose the Right Materials: Select packaging that fits your product size, weight, and fragility.

- Partner Strategically: Work with vendors and clients who are open to participating in a returnable system.

- Monitor and Optimize: Utilize software to track packaging assets and continually refine the process.

Conclusion: Is It Worth It?

So, are Returnable Packaging Solutions right for small businesses?

The answer depends on your business model, industry, and long-term goals. While the initial investment and logistical challenges may deter some, the benefits—cost savings, improved sustainability, and better product protection—make it a worthwhile consideration for many.

If you’re ready to explore how to integrate returnable systems efficiently, look for partners with experience in durable transport packaging. Companies like Kole Pallet specialize in providing tailored solutions that align with your operational needs and growth trajectory.

In a market where every dollar and customer impression counts, going returnable might just be the edge your small business needs.

Frequently Asked Questions:-

1. What are Returnable Packaging Solutions?

- Returnable packaging solutions are reusable containers, pallets, and crates that may be used several times in a supply chain. Unlike single-use packaging, these materials are returned after delivery for future shipments, helping reduce waste and lower long-term costs.

2. Are returnable packaging systems affordable for small businesses?

- While the initial cost may be greater, returnable packaging might become more cost-effective over time. Small businesses can start small with pilot programs to evaluate ROI before scaling up.

3. Which industries gain the most from returnable packaging solutions?

- Returnable packaging is especially beneficial in industries such as food and beverage, automotive, retail, manufacturing, and e-commerce, owing to frequent shipments and the necessity for product safety and sustainability.

4. How do small businesses manage the return process?

- Small businesses can manage returns through third-party logistics, customer cooperation, and technology like barcoding or RFID tags. Starting with a controlled, regional rollout helps simplify the reverse logistics process.

5. Can a business such as Kole Pallet assist with implementation?

- Yes, companies like Kole Pallet offer customized returnable packaging systems, helping small businesses select the right materials, streamline logistics, and implement tracking for efficient reuse and return.