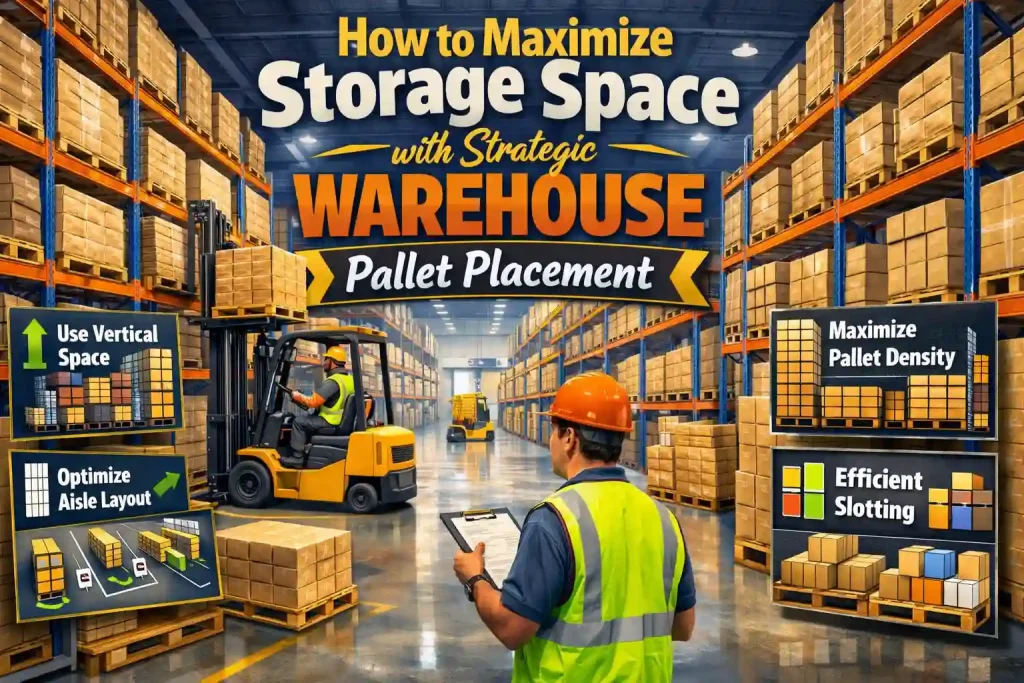

In today’s fast-paced logistics and supply chain environment, storage efficiency can make or break warehouse profitability. As inventory volumes grow and customer expectations tighten, businesses must find smarter ways to use every square foot available. One of the most effective yet often overlooked strategies lies in how pallets are placed and managed. A well-planned Warehouse Pallet layout not only improves storage density but also enhances accessibility, safety, and operational speed.

Many warehouses struggle with wasted vertical space, congested aisles, or inefficient picking routes simply because pallet placement was never strategically designed. Instead of expanding facilities or investing in costly automation, companies can unlock hidden capacity by rethinking how pallets are stored, stacked, and moved. Strategic pallet placement aligns storage systems with inventory characteristics, material handling equipment, and workflow patterns. This article explores proven methods, industry insights, and practical techniques to help you maximize storage space through smarter pallet placement, all while maintaining safety and efficiency.

Table of Contents

ToggleUnderstanding the Role of Pallet Placement in Warehouse Efficiency

Pallet placement is more than deciding where items sit on the floor or rack. It directly impacts how efficiently a warehouse operates on a daily basis. According to industry studies, poor layout and storage planning can reduce warehouse capacity utilization by up to 30%. That’s a significant loss for any operation dealing with high inventory turnover.

Strategic placement ensures that high-demand items are easy to access, reducing travel time for forklifts and pickers. It also improves load stability and minimizes product damage. When pallets are placed with consideration for weight distribution, SKU velocity, and handling methods, warehouses experience smoother workflows and fewer bottlenecks.

The Connection Between Space Utilization and Productivity

Efficient pallet placement boosts productivity by reducing unnecessary movement. Shorter travel distances translate into faster picking and replenishment cycles. Over time, these small gains add up, allowing warehouses to process more orders without increasing labor costs.

Analyzing Warehouse Layout Before Placing Pallets

Before rearranging pallets, it’s essential to analyze your existing warehouse layout. Every facility has unique constraints, such as ceiling height, column placement, and dock locations. Understanding these factors helps determine the most effective pallet placement strategy.

Start by mapping out storage zones, aisles, and work areas. Identify underutilized vertical space and areas prone to congestion. Data from warehouse management systems (WMS) can reveal slow-moving versus fast-moving inventory, which is critical for placement decisions.

Slotting Analysis for Smarter Decisions

Slotting analysis involves assigning the right products to the right locations. High-frequency SKUs should be placed closer to shipping areas, while slower-moving items can be stored higher or farther away. This approach alone can improve picking efficiency by up to 20%, according to logistics benchmarks.

Choosing the Right Pallet Racking Systems

Not all pallet racking systems are created equal. Selecting the right system plays a major role in maximizing storage space. Common options include selective racking, drive-in racking, push-back racking, and pallet flow systems.

Selective racking offers easy access to every pallet but may sacrifice density. Drive-in and drive-through systems increase density by reducing aisle space, making them ideal for high-volume, low-SKU environments. Push-back and flow racks use gravity to improve accessibility while maintaining higher storage density.

Matching Racking Systems to Inventory Types

Perishable goods benefit from pallet flow systems that support FIFO (first-in, first-out) rotation. Bulk storage of uniform items works well with drive-in racking. Aligning racking systems with product characteristics ensures optimal use of space without compromising inventory control.

Leveraging Vertical Space with Smart Pallet Stacking

One of the most common storage inefficiencies is underused vertical space. Many warehouses fail to stack pallets high enough due to safety concerns or outdated practices. With proper equipment and training, vertical stacking can significantly increase capacity.

Modern forklifts and reach trucks are designed to handle higher lifts safely. However, pallet quality, load stability, and rack ratings must always be taken into account. OSHA reports indicate that improper stacking is a leading cause of warehouse accidents, highlighting the importance of proper planning.

Safety Guidelines for High Stacking

Ensure loads are distributed evenly, and pallets are in good condition. Use load bars, netting, or stretch wrap to secure items. Regular inspections and employee training help maintain safety while maximizing vertical storage.

Optimizing Aisle Width and Traffic Flow

Aisle design directly affects how many pallets can fit in a warehouse. Narrower aisles allow for more storage rows, but they require specialized material handling equipment. Many warehouses are transitioning to narrow aisle or very narrow aisle (VNA) configurations to increase capacity by up to 40%.

Traffic flow should be clearly defined to prevent congestion and accidents. One-way aisles, marked pedestrian zones, and designated staging areas improve safety and efficiency. Strategic pallet placement within these aisles ensures smooth operations even in high-density environments.

Balancing Density and Accessibility

While high-density storage is appealing, it should not come at the cost of accessibility. The goal is to find a balance where pallets are stored compactly but can still be retrieved quickly when needed.

Using Technology to Enhance Pallet Placement Strategies

Technology plays a growing role in optimizing pallet placement. Warehouse management systems can analyze inventory data and recommend optimal storage locations. Some advanced systems even use AI to adjust placement dynamically based on demand patterns.

Barcode scanning and RFID tracking improve visibility, ensuring pallets are always stored and retrieved correctly. Real-time data helps managers identify inefficiencies and make informed decisions about layout changes.

Data-Driven Continuous Improvement

By regularly reviewing performance metrics such as pick rates, space utilization, and error rates, warehouses can continuously refine pallet placement strategies. Small adjustments guided by data can lead to substantial long-term gains.

Conclusion

Maximizing storage space is not about cramming more inventory into a warehouse; it’s about using space intelligently. Strategic pallet placement improves capacity, efficiency, and safety without requiring expensive expansions. By analyzing warehouse layouts, choosing appropriate racking systems, leveraging vertical space, and optimizing aisle design, businesses can unlock hidden potential within their existing facilities.

Equally important is adopting a mindset of continuous improvement. As inventory profiles and customer demands evolve, pallet placement strategies should adapt accordingly. Technology and data insights make it easier than ever to refine these decisions and stay competitive. Whether you operate a small distribution center or a large-scale fulfillment hub, thoughtful planning around pallet placement can deliver measurable results. Companies that invest time in optimizing how pallets are stored often find themselves better prepared for growth, seasonal spikes, and operational challenges. For organizations exploring quality pallet solutions and smarter storage practices, options like Kole Pallet can play a role in supporting long-term warehouse efficiency and scalability.

Frequently Asked Questions:-

1. Why is strategic pallet placement important in a warehouse?

- Strategic pallet placement helps warehouses use available space more efficiently while improving workflow and safety. Proper placement reduces travel time, prevents congestion, and allows faster picking and replenishment, which can significantly lower operational costs.

2. How does pallet placement impact warehouse storage capacity?

- Effective pallet placement can increase storage capacity by optimizing vertical space, reducing wasted aisle areas, and improving racking utilization. Many warehouses can unlock 20–40% more space without expanding by redesigning pallet layouts.

3. What is the best pallet racking system for maximizing storage space?

- The best racking system depends on inventory type and turnover rate. Selective racking offers easy access, while drive-in, push-back, and pallet flow systems provide higher density for bulk or high-volume storage environments.

4. How can warehouses safely maximize vertical pallet stacking?

- Vertical stacking can be maximized by using rated racking systems, high-quality pallets, and modern material handling equipment. Regular inspections, proper load distribution, and employee training are essential to maintain safety.

5. Can technology help improve pallet placement decisions?

- Yes, warehouse management systems and data analytics help identify optimal pallet locations based on demand, SKU velocity, and space availability. Technology-driven placement reduces errors, improves efficiency, and supports continuous layout optimization.