In today’s highly interconnected and competitive global marketplace, Indian manufacturers have carved out a strong position in numerous industries — from automotive and pharmaceuticals to logistics and industrial equipment. Among these, metal pallet manufacturer in India have become vital players in supporting global trade and supply chain operations.

The humble metal pallet — once seen as a simple logistical tool — has evolved into a key component of efficient, sustainable, and safe goods transportation. Indian manufacturers are now setting international benchmarks for quality, innovation, and cost-efficiency.

This blog explores how metal pallet manufacturers in India compete on the world stage, what strategies set them apart, and how they continue to strengthen their foothold in the global supply chain.

Table of Contents

Toggle1. The Rise of Metal Pallets in Global Logistics

Over the past decade, the global supply chain has undergone dramatic transformations. With the boom in e-commerce, manufacturing, and international trade, companies are prioritizing efficiency, durability, and sustainability in their logistics solutions.

While wooden pallets have long been a staple, metal pallets are increasingly being recognized for their strength, longevity, and recyclability. Industries that require heavy-duty, hygienic, and fire-resistant solutions — such as pharmaceuticals, chemicals, food processing, and automotive manufacturing — are shifting to metal alternatives.

This transition has opened enormous opportunities for metal pallet manufacturers in India, who have quickly adapted to meet rising international demand.

2. India’s Strategic Advantage in Manufacturing

India holds several unique advantages that enable its manufacturers to compete globally:

a. Cost Efficiency with Quality

Indian manufacturers have mastered the art of combining affordability with high-quality production. Lower labor costs, a large pool of skilled engineers, and efficient resource utilization help Indian companies offer competitive pricing without compromising on international quality standards.

b. Abundance of Raw Materials

India’s strong base in steel and metal production provides a major supply advantage. The easy availability of raw materials reduces procurement costs and lead times — critical factors in global logistics.

c. Government Support for Export and Manufacturing

Initiatives such as Make in India and Atmanirbhar Bharat have spurred industrial innovation, automation, and export-focused growth. Subsidies, tax incentives, and simplified export regulations further empower metal pallet producers to expand their global reach.

d. Technological Advancement

Indian manufacturers have embraced automation, computer-aided design (CAD), and robotic welding. These innovations enhance precision, reduce waste, and ensure product consistency — all crucial for meeting international standards.

3. Meeting Global Quality and Safety Standards

One of the most important ways Indian companies compete internationally is by adhering to global quality norms.

Leading metal pallet manufacturers in India design and produce pallets that meet ISO, ASTM, and EN standards. These certifications ensure that every pallet is capable of handling heavy loads, maintaining structural integrity, and enduring harsh environmental conditions.

Moreover, many Indian firms conduct rigorous testing on factors such as:

- Load-bearing capacity

- Corrosion resistance

- Heat and fire tolerance

- Surface finish and anti-slip properties

By aligning with the quality benchmarks set by global logistics and warehousing giants, Indian manufacturers are recognized as reliable partners in the global supply chain.

4. Innovation in Design and Functionality

Competition in the international market demands more than just a price advantage — innovation is key.

Indian companies are actively developing customized and modular metal pallet designs to meet the diverse needs of different industries. For instance:

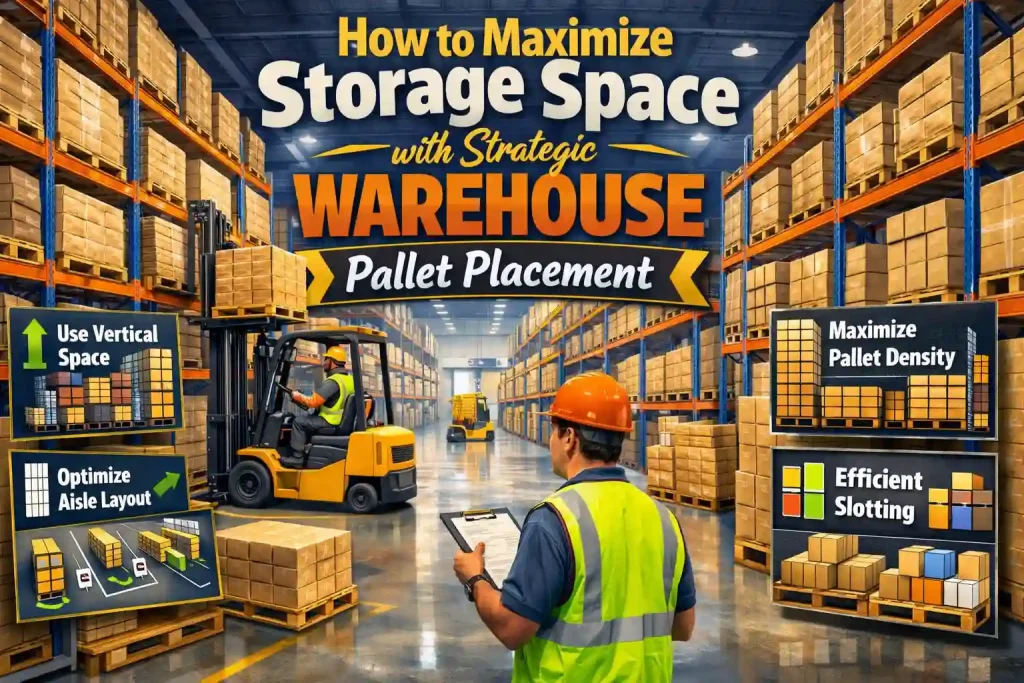

- Nestable pallets for space optimization in shipping containers.

- Stackable pallets for warehousing efficiency.

- Heavy-duty pallets for the automotive and defense sectors.

- Hygienic stainless-steel pallets for pharmaceuticals and food processing.

By tailoring designs to end-use industries, Indian manufacturers ensure compatibility with automated material handling systems, forklifts, and robotic palletizers used in modern warehouses.

Additionally, sustainable production practices — such as the use of recycled metals and eco-friendly coatings — are being integrated to appeal to environmentally conscious buyers across Europe, North America, and the Middle East.

5. Logistics and Export Capabilities

Manufacturing excellence is only one part of the story. Efficient logistics, packaging, and export management determine whether a company can truly compete globally.

Indian exporters have honed these skills by leveraging the country’s improving infrastructure:

- Port connectivity: With major ports like Mumbai, Chennai, and Mundra, manufacturers can ship globally at competitive freight rates.

- Logistics hubs and corridors: The Delhi-Mumbai Industrial Corridor and other projects have streamlined inland transportation.

- Digital documentation and customs clearance: Modernized export processes minimize delays and enhance reliability.

This robust export ecosystem enables metal pallet manufacturers to fulfill large international orders within tight timelines — a key competitive advantage in global supply chains.

6. Sustainability: The New Competitive Edge

Sustainability is no longer a choice; it’s a worldwide commercial requirement.

Indian metal pallet producers are investing in green manufacturing processes, reducing energy consumption, and minimizing waste. Many are also recycling scrap metal and adopting solar-powered fabrication units to lower their carbon footprint.

Compared to wooden pallets, metal pallets have a significantly longer lifespan and can be fully recycled at the end of use. This makes them a sustainable choice for global companies aiming to meet ESG (Environmental, Social, and Governance) goals.

By aligning their products and operations with global sustainability standards, Indian manufacturers are positioning themselves as partners in responsible, eco-friendly logistics.

7. Competing on Price, Reliability, and Service

While cost-competitiveness remains a major advantage, Indian manufacturers understand that long-term success depends on reliability and service.

Many exporters now provide:

- End-to-end solutions — from design to delivery.

- After-sales support and warranty services.

- Just-in-time delivery systems to international clients.

- Partnership-based contracts for continuous supply.

These value-added services differentiate Indian companies from low-cost competitors and build lasting business relationships.

8. Strategic Partnerships and Global Collaborations

To further enhance competitiveness, Indian manufacturers are forming strategic partnerships with global logistics companies, distributors, and engineering firms.

Such collaborations allow for:

- Access to advanced technologies and design expertise.

- Entry into new markets through shared distribution networks.

- Joint development of innovative pallet systems for specialized industries.

By blending local efficiency with global expertise, Indian metal pallet manufacturers strengthen their position as trusted suppliers on the international stage.

9. Challenges and How Manufacturers Overcome Them

Despite impressive growth, manufacturers face several challenges in maintaining global competitiveness. These include:

- Volatility in raw material prices (especially steel and aluminum).

- Currency fluctuations are affecting export margins.

- Complex international regulations on safety and environmental compliance.

- Competition from countries like China and Vietnam.

However, Indian manufacturers have turned these challenges into opportunities through smart strategies:

- Long-term contracts with steel suppliers for price stability.

- Diversification into multiple export markets to mitigate currency risk.

- Continuous training programs for workforce skill enhancement.

- Automation and lean manufacturing to reduce production costs.

By proactively addressing these issues, they ensure steady growth and sustained global competitiveness.

10. Future Outlook: India’s Role in the Next-Gen Supply Chain

The future of global logistics will be shaped by automation, digital tracking, and sustainability — and India is poised to play a leading role.

Metal pallet manufacturers are already integrating IoT (Internet of Things) and RFID tracking systems into their pallets. These smart pallets enable real-time tracking of goods, preventive maintenance alerts, and optimized supply chain visibility.

As global companies look for dependable, sustainable, and tech-enabled logistics partners, India’s reputation as a reliable manufacturing hub will only strengthen.

Furthermore, with rising trade diversification and the global trend of “China+1” sourcing strategies, many international buyers are turning to India for long-term partnerships in pallet manufacturing and supply chain equipment.

Conclusion:-

The success story of Indian metal pallet manufacturers is a reflection of the country’s broader industrial transformation. By combining innovation, cost efficiency, sustainability, and service excellence, they have earned a respected position in the global supply chain.

Every metal pallet manufacturer in India plays a crucial role in ensuring goods move safely, efficiently, and sustainably across continents. As global trade continues to evolve, their ability to adapt and innovate will be the key to long-term success.

Among the rising names in this space, Kole Pallet stands out as a brand that embodies the best of Indian manufacturing — precision engineering, global quality standards, and a deep commitment to customer satisfaction. The future of metal pallet manufacturing in India is bright, resilient, and ready to take on the world.

Frequently Asked Questions:-

1. Why are metal pallets preferred over wooden pallets in global supply chains?

- Metal pallets are stronger, more durable, and resistant to moisture, fire, and pests compared to wooden pallets. They also have a longer lifespan and are fully recyclable, making them a more sustainable choice for industries that prioritize hygiene and safety, such as pharmaceuticals, food processing, and manufacturing.

2. What makes Indian metal pallet manufacturers competitive internationally?

- Indian manufacturers combine cost efficiency with high-quality production. They have access to abundant raw materials, skilled labor, and advanced manufacturing technologies. Additionally, government initiatives like Make in India and strong export infrastructure help Indian companies compete effectively on a global scale.

3. Are metal pallets suitable for all industries?

- Yes, metal pallets can be customized to suit various industries. Heavy-duty steel pallets are ideal for automotive and construction sectors, while stainless-steel pallets are perfect for cleanroom and food-grade applications. Their adaptability makes them versatile across multiple industries.

4. How do metal pallet manufacturers in India ensure quality and compliance?

- Leading metal pallet manufacturers in India adhere to international standards such as ISO, ASTM, and EN. They perform rigorous quality checks on load capacity, corrosion resistance, and safety features to ensure the pallets meet global logistics requirements.

5. What role does Kole Pallet play in India’s global pallet manufacturing industry?

- Kole Pallet is recognized as one of the leading innovators in metal pallet manufacturing in India. The company focuses on precision engineering, sustainability, and customer-focused solutions, helping Indian-made pallets gain a strong reputation in the global supply chain.