Running an efficient warehouse operation is all about smart choices. From the way you store products to how quickly you can move inventory, every detail makes a difference. One often-overlooked element that plays a massive role in smooth operations is the pallet. Pallets may look simple, but selecting the right ones can directly impact your storage capacity, transportation costs, and overall safety.

If you’re wondering how to choose the right warehouse pallet for your business, this guide will walk you through everything you need to know—from pallet materials and sizes to industry-specific considerations.

Table of Contents

ToggleWhy Choosing the Right Pallet Matters?

Many business owners think of pallets as generic platforms, but in reality, they are the backbone of logistics. The wrong pallet can slow down your workflow, increase costs, and even cause safety issues. Here’s why the choice matters:

- Efficiency: The right pallet size and material make loading, unloading, and stacking easier.

- Safety: Stronger pallets prevent accidents by securing products.

- Cost Savings: Durable pallets reduce replacement expenses and minimize product damage.

- Sustainability: Eco-friendly pallets align with corporate responsibility goals.

By carefully evaluating your options, you set up your warehouse for smoother operations and long-term cost efficiency.

Step 1: Understand Your Storage and Handling Needs

Before diving into pallet types, take a close look at your warehouse setup. Ask yourself these questions:

- What type of goods are you storing—heavy machinery, perishable items, or lightweight products?

- How frequently are pallets moved in and out?

- Do you use forklifts, pallet jacks, or automated systems?

- What are your weight requirements per pallet?

Your answers will help determine whether you need heavy-duty plastic, cost-effective wood, or even metal pallets designed for specific industries.

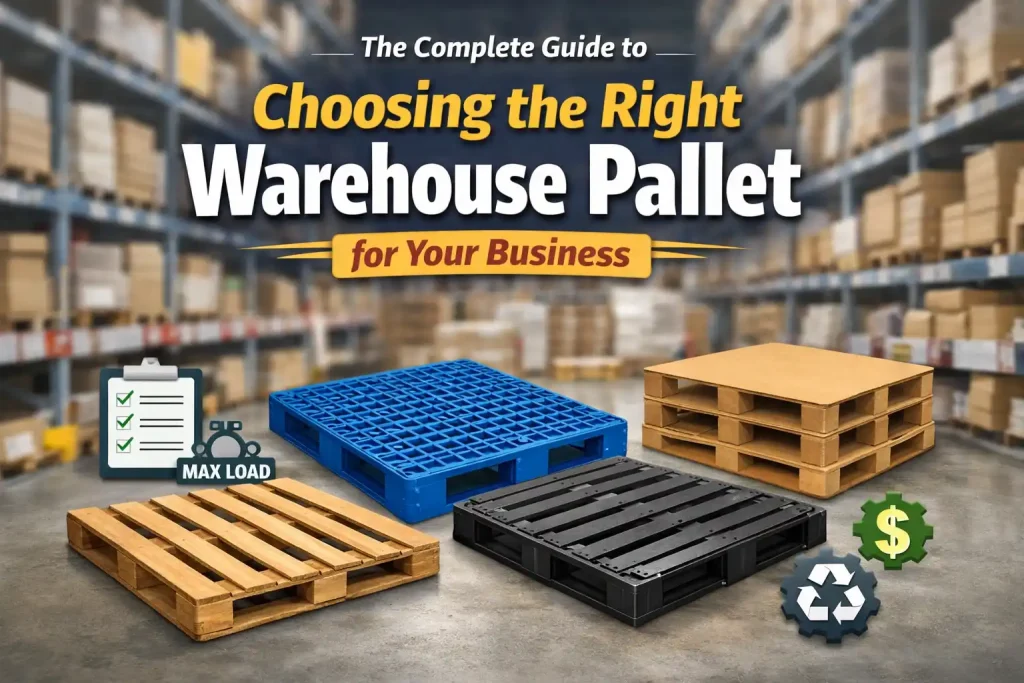

Step 2: Learn About Different Pallet Materials

Not all pallets are created equal. Each material has strengths and weaknesses, so choosing the right one for your warehouse is key.

Wooden Pallets

- Pros: Affordable, widely available, and easy to repair.

- Cons: Can splinter, absorb moisture, and may not meet hygiene standards for food or pharmaceuticals.

- Best For: General storage, short-term use, and industries with lower hygiene requirements.

Plastic Pallets

- Pros: Durable, resistant to chemicals and moisture, lightweight, and reusable.

- Cons: Higher upfront cost and more difficult to repair if broken.

- Best For: Food, pharmaceuticals, and long-term logistics operations where cleanliness is critical.

Metal Pallets

- Pros: Extremely strong, long-lasting, and resistant to fire or pests.

- Cons: Expensive and heavier to move.

- Best For: Heavy-duty industries like automotive, construction, and defense.

Presswood or Composite Pallets

- Pros: Lightweight, nestable for space-saving, and export-compliant.

- Cons: Limited lifespan compared to wood or plastic.

- Best For: Exporting goods and one-way shipments.

By matching material type with your operational demands, you’ll ensure efficiency and reduce waste.

Step 3: Choose the Right Pallet Size

Pallet size plays a crucial role in maximizing warehouse space. Choosing a standard size ensures compatibility with your equipment and storage systems.

- 48” x 40”: The most common size in North America, ideal for general use.

- 42” x 42”: Popular in the telecommunications and paint industries.

- 48” x 48”: Often used in the chemical and beverage sectors.

- European Pallets (1200mm x 800mm): Standard across Europe and compliant with international shipping requirements.

Tip: Always check with your shipping partners and warehouse racking systems before committing to a specific size.

Step 4: Consider Load Capacity

Weight capacity is one of the most important factors when selecting a pallet. Overloading can lead to accidents, damaged goods, and faster pallet wear.

- Static Load: The weight a pallet can hold while stationary.

- Dynamic Load: The weight that it can support while being moved.

- Racking Load: The weight it can support when stored in a racking system.

For example, a wooden pallet may hold up to 3,000 lbs dynamically, while plastic pallets often support 5,000 lbs or more. Always evaluate your typical load before purchasing.

Step 5: Think About Sustainability

Biodiversity is no longer a choice; it is a corporate obligation. Many companies are switching to recyclable or reusable pallets to reduce waste. Plastic pallets, for instance, can be recycled at the end of their lifespan, while wood pallets are repairable and biodegradable.

By choosing eco-friendly pallets, you not only reduce your carbon footprint but also strengthen your brand reputation with environmentally conscious customers.

Step 6: Account for Industry Regulations

Depending on your industry, certain pallet types may be required by law or certification bodies.

- Food and Beverage: Plastic pallets are often preferred because they meet hygiene standards and resist moisture.

- Pharmaceuticals: Regulations demand clean, chemical-resistant pallets to prevent contamination.

- Exporting Goods: Many countries require pallets that comply with ISPM-15 standards to prevent pest transfer, meaning heat-treated or fumigated wood pallets are necessary.

Failing to follow these rules can result in fines, shipment rejections, or damaged relationships with clients.

Step 7: Evaluate Long-Term Costs

While it may be tempting to choose the cheapest option, it’s important to look beyond the purchase price.

- Wood Pallets: Cheaper upfront but need frequent replacement.

- Plastic Pallets: Higher cost initially but last longer and reduce replacement expenses.

- Metal Pallets: Costly but virtually indestructible for industries that need long-term solutions.

Consider your business’s scale and frequency of use to decide which option is most cost-effective over time.

Step 8: Factor in Warehouse Design and Equipment

Your pallet choice should align with your existing warehouse infrastructure:

- Racking Systems: Some pallets are better suited for open racks, while others need solid shelving support.

- Forklifts and Pallet Jacks: Ensure compatibility with your handling equipment.

- Automation: If you use automated systems, you’ll need pallets with consistent dimensions and durability.

Making sure your pallets fit seamlessly into your operations avoids costly inefficiencies.

Step 9: Prioritize Safety

Pallet safety isn’t just about protecting products; it’s also about protecting your workforce. Damaged or weak pallets can cause injuries during lifting, stacking, or transportation. Regular inspections and choosing the right pallet material for your loads will go a long way toward maintaining a safe workplace.

Common Mistakes to Avoid

When selecting pallets, businesses often make these costly mistakes:

- Choosing solely based on price instead of long-term value.

- Ignoring weight limits and causing pallet failure.

- Overlooking compatibility with racks and handling equipment.

- Forgetting about export requirements.

- Neglecting employee training on safe pallet handling.

Avoiding these pitfalls will save time, money, and frustration.

Final Thoughts: Making the Best Choice

Pallets may seem like a small detail, but they hold the weight—literally—of your entire operation. From the type of materials and sizes to compliance with industry standards, every decision influences your bottom line.

When evaluating your options, remember to:

- Assess your storage and handling needs.

- Consider durability versus upfront costs.

- Prioritize safety and compliance.

- Seek out eco-friendly solutions that align with your brand’s values.

Choosing the right warehouse pallet is not just about storage—it’s about efficiency, safety, and long-term success. For businesses seeking trusted solutions, Kole Pallet offers reliable options tailored to modern logistics needs.

Frequently Asked Questions:-

1. What is the most common type of pallet used in warehouses?

- The most widely used pallet is the standard 48” x 40” wooden pallet. It’s affordable, versatile, and suitable for general storage and shipping needs. However, industries with stricter hygiene requirements often prefer plastic pallets.

2. How do I know which pallet size is right for my business?

- The best pallet size depends on your warehouse racking system, the type of products you store, and your shipping requirements. Standard sizes like 48” x 40” are versatile, while industries such as chemicals or beverages may prefer larger 48” x 48” pallets. Always ensure your pallet size is compatible with your equipment.

3. Are plastic pallets worth the higher cost compared to wooden pallets?

- Yes, in many cases. Plastic pallets are more durable, resistant to chemicals and moisture, and reusable, which makes them cost-effective in the long run. While the initial investment is higher, they reduce replacement costs and are ideal for food, pharmaceutical, and export industries.

4. What safety precautions should I take with pallets in my warehouse?

- Inspect pallets regularly for cracks, splinters, or weaknesses. Train staff on safe lifting and stacking practices, and never exceed the recommended weight limits. Proper maintenance and choosing the right material also go a long way in preventing accidents.

5. Do I need special pallets for exporting goods internationally?

- Yes. Many countries require compliance with ISPM-15 standards for wood pallets, meaning they must be heat-treated or fumigated to prevent pest transfer. Alternatively, you can use plastic or presswood pallets, which are often export-compliant without additional treatment.